| Hint | Food | 맛과향 | Diet | Health | 불량지식 | 자연과학 | My Book | 유튜브 | Frims | 원 료 | 제 품 | Update | Site |

|

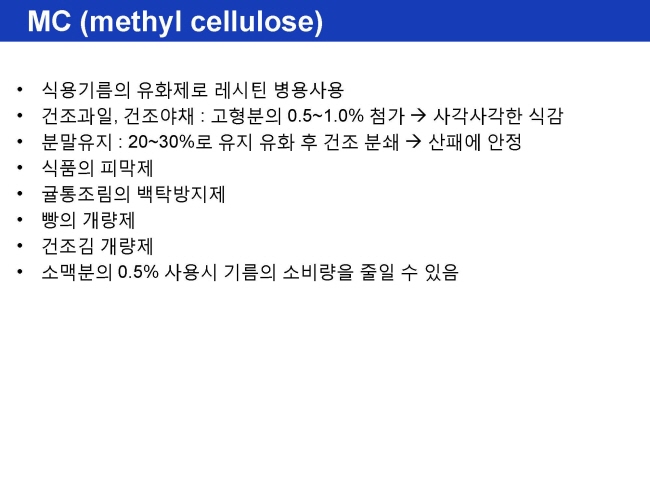

물성 ≫ 증점 ≫ 증점제 종류 증점제 : 셀룰로스계 Methyl cellulose cellulose - Methyl cellulose - Fat holdout 거의 유일하게 고온에서 점도증가(겔화), 빵의 배터에서 튀김시 피막형성, 지방흡입차단 : fat holdout - Methyl celllulose - Hydroxypropylcellulose - Methylhydroxypropylcellulose  Making Things Melt in Weird Ways: Methylcellulose and Maltodextrin 출처 : http://mom.girlstalkinsmack.com/family/modern-industrial-chemicals-(part-5)---%E2%80%9Cmelts%E2%80%9D-as-it-cools--methylcellulose---hot-marshmallows.aspx At a high level, making gels is about transforming liquids into solids. In addition to creating gels, though, modern food additives can be used to alter other properties of foods, and another area of play in the modernist kitchen is that of melting. How can we make things change state in unexpected ways? 4.1. “Melts” as it cools: Methylcellulose Methylcellulose has the unusual property of getting thicker when heated (thermo-gelling in chem-speak). Take jam: when heated, it loses its gel structure (the pectin melts), causing it to flow out of things like jam-filled pastries. Adding methylcellulose prevents this by causing the jam to “gel” into a solid under heat. And since methylcellulose is thermoreversible, upon cooling after baking, the jam returns to its normal consistency. Note: Hollywood uses methylcellulose to make slime. Add a bit of yellow and green food dye, and you’ve got yourself Ghostbusters-style slime. To get good consistency, whisk it vigorously to trap air bubbles into the mixture. Methylcellulose has been used in some modernist cuisine dishes for its thermo-gelling effects. One famous example is “Hot Ice Cream” in which the “ice” cream is actually hot cream that’s been set with methylcellulose. As it cools to room temperature, it melts. Instructions for use. Dissolve methylcellulose into hot water (above 122°F / 50°C) and then whisk while cooling down. Mixing it directly in cold water can be difficult because the powder will clump up as it comes into contact with water. In hot water, though, the powder doesn’t absorb any water, allowing it to be uniformly mixed. It’s easiest to stir in 1.0% to 2.0% (by weight) into your liquid and let it rest overnight in the fridge to dissolve fully. You can then experiment with setting the liquid. Try baking a small dollop of it, or dropping it by the ice cream scoopful into a pan of simmering water. Uses. Commercial applications use it to prevent “bake-out” of fillings in baked goods. Methylcellulose also has high surface activity, meaning that it acts as an emulsifier by keeping oil and water from separating, so it is also used in low-oil and no-oil dressings and to lower oil absorption in fried foods. Note: Methylcellulose increases surface tension—well, actually, “interfacial tension” because “surface” refers to a two-dimensional shape—which is why it works as an emulsifier. Origin and chemistry. Methylcellulose is made by chemically modifying cellulose (via etherification of the hydroxyl groups). There can be great variation between types and derivatives of methylcellulose, in terms of thickness (viscosity), gelling temperature (122–194°F / 50–90°C), and strength of gel (ranging from firm to soft). If you’re having problems getting your methylcellulose to set, check the specifications of the type you have. When cold (on left), water molecules are able to form water clusters around the methylcellulose molecule. With sufficient heat—around 122°F / 50°C—the water clusters are destroyed and the methylcellulose is able to form crosslinks, resulting in a stable gel at higher temperatures. 자료 출처 : Polymers 2015, 7(5), 777-803; doi:10.3390/polym7050777 Methylcellulose, a Cellulose Derivative with Original Physical Properties and Extended Applications Pauline L. Nasatto 1,2,*, Frédéric Pignon 2,3, Joana L. M. Silveira 1, Maria Eugênia R. Duarte 1, Miguel D. Noseda 1 and Marguerite Rinaudo 4  Figure 9. Schematic drawing showing gelation through the hydrophobic effective units of methylcellulose. At lower temperatures, the hydrophobic association is possible from the hydrophobic effective units. During heating, the gel is formed with the hydrophobic junctions consisting of such hydrophobic effective units and the mean length Me between two junctions remains constant when the gelling temperatures are higher than 42.5 °C. Reproduced with permission from American Chemical Society, 2001 [15]. Between 55 and 75 °C, a large increase of G' is observed depending on the polymer concentration (when it is higher than C*) and the turbid strong gel is formed corresponding to the second step of gelation, together with the phase separation [20]. This second step has been more widely studied in the literature [6,22,64]. The mechanism of phase separation observed over 50 °C, dependent on the chemical structure, polymer concentration and molecular weight, is still under discussion. A spinodal decomposition proposed by Fairclough et al. [62] increases concentration fluctuations during the phase separation trapped by gelation, the two processes occur almost simultaneously. On the contrary, Arvidson et al. [6] used rheological measurements and suggested that thermogelation of methylcellulose may proceed by a nucleation and growth mechanism. In the case of the strong gels, the gel network structure may be formed on the basis of hydrophobically associating domains (the junctions) connected by a mean chain length of 27,500 g/mol as shown in Figure 9. The elastic modulus G' was studied as a function of polymer concentration and molecular weight at 50 °C and 75 °C as shown in Figure 10. At 50 °C, corresponding to the end of first step of gelation, no clear dependency on molecular weight and concentration was noticed. It was shown that G' varies from 1 to 10 Pa for all tested systems [20].     |

||||

|

|

|||